Traeger is always looking for way to innovate in the outdoor cooking category. Be it through an induction cooktop on the new Timberline or a new griddle line that they are possibly working on. Another way they are possibly looking to add new features to their smoker line-up is through cold smoke grilling modes.

As we noted in our comparison between Traeger and Pit Boss, the temperature on a Traeger grill can get about 15 degrees F lower than other competitors. Through a patent that was released, we learned that Traeger is working on smoke modes that go even lower. They’ve been testing going as low as 80 degrees F.

The introduction of cold smoke grilling modes would add more versatility to Traeger grills. Notably, it would be useful for food like smoked salmon or smoked cheese.

Through testing, Traeger has learned that a cold smoke environment can be achieved in different ways. One way, outlined in the patent, is through dropping pellets at an extremely low rate into the firepot and heating them individually until the stage that smoke is produced.

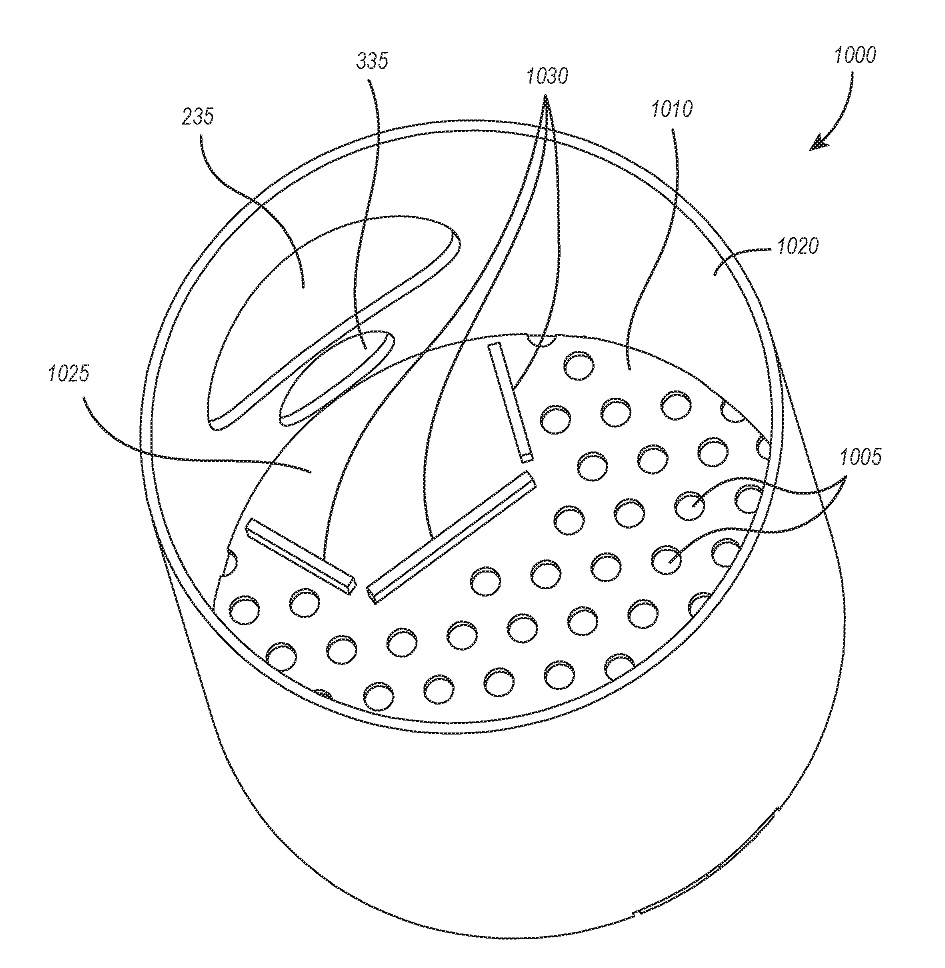

They’ve also been testing adding holes, possibly covered in a screen, to the firepot to increase air circulation. You’ll notice in the image below a perforation that add more control to how the pellets are burned. It’s worth noting that this is the second patent that we’ve seen holes in the firepot. It was also present in one on easier methods for ash cleaning.

To understand how they plan to achieve cold smoke, we have to look at the stages of wood burning. There are different organization that define them differently, but the way that Traeger defines them is as follows.

Stage 1 – Moisture Evaporation

During this stage various volatile, including water, begin to evaporate out of the wood. After it reaches 212 degrees F, water has evaporated out and the wood is dry enough for initial combustion. During this stage heat is absorbed and the the wood breaks down to 450 degrees F to release gases.

Stage 2 – Hydrocarbon Vaporization

During this stage the structure of the wood molecules begin to breakdown producing combustible gases. Heat is being absorbed during this stage and visible smoke production begins.

Stage 3 – Gas Vapor Ignition and Combustion

This stage occurs above about 540 degrees F, where carbon reacts with oxygen to form combustible gases. The smoke produced in this stage is less visible and combustion is occurring. Higher levels of oxygen in this stage will allow combustion to occur at lower temperatures.

Stage 4 – Char Burning

During this stage the only remaining combustible material is the wood charcoal, which doesn’t produce much, if any, flame.

How to Get “Good” Smoke

Creosote comes from wood combustion and contains lignin in the form of guaiacol and syringol. Syringol is the chemical mainly responsible for the smoke smell that we know and love, while guaiacol is what contributes to the smokey taste in food. These are broken down in Stage 3, in the temperature range of about 540 degrees F to about 1,000 degrees F. The preferred range for good smoke production is from about 752 degrees F to about 923 degrees F.

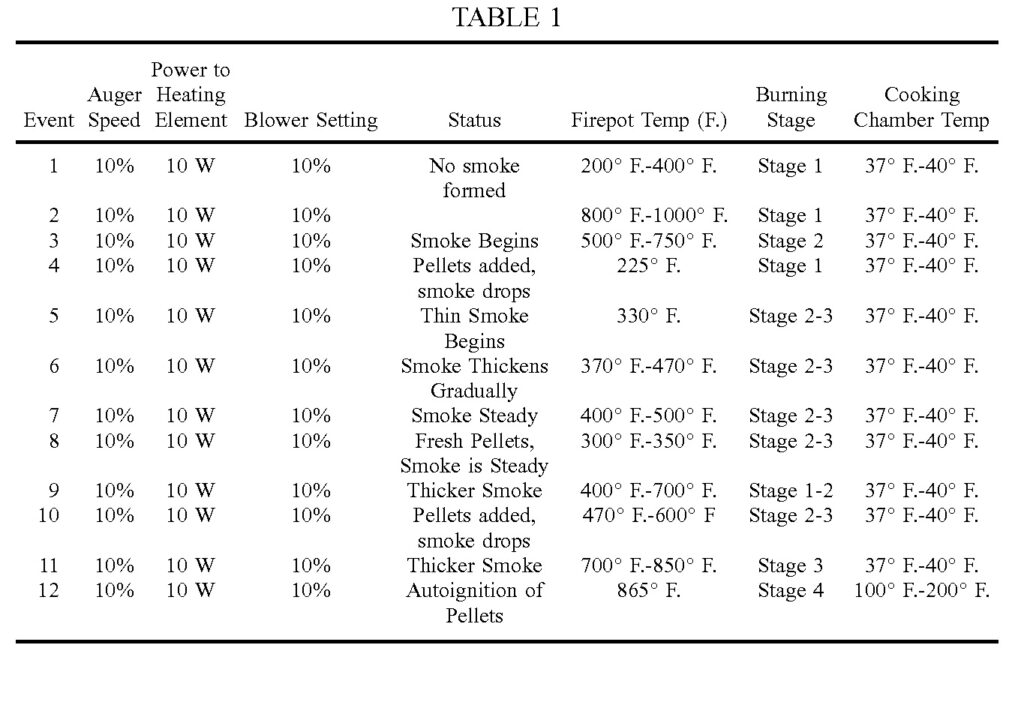

Below are tests that Traeger has performed where they were able to control the auger speed and blower settings to increase the firepot temp enough to get good smoke, without increasing the temperature of the cooking chamber.

What Traeger is mainly targeting in their test is shown in Events 9 and 10 in the table above. That’s where good smoke flavor is produced, without increasing the cook chamber temperature. They also noted in their patent that they’ve shown in their testing that they can move between Events by modulating the auger speed and blower settings.

Summary

Traeger has shown in their cold smoke grill modes patent that they can achieve good tasting smoke in the cook chamber at low temperatures. They do this by minimizing the amount of pellets burned at a time, so the temperature in the firepot rises, without dramatically increasing the temperature in the cook chamber.

It would be great to have the added option of cold smoke modes. We hope that development continues and this patent results in new technology for the consumer.