As we mentioned in our previous article discussing Traeger rumors about a new BBQ sauce, new rub and a new grill, Traeger’s strategy for innovation is to release new features on their premium model and then cascade those features down to other models. The new Timberline XL was released recently with a host of new features and capabilities. One of those was an easy clean-out system for ash and grease called The EZ-Clean™ Grease & Ash Keg, as shown in the video below.

On the Traeger Pro and Traeger Ironwood models, they have an external grease collection and you have to use a shop vac to clean the ash out of the inside of the grill as part of routine maintenance. Other manufacturers, such as Camp Chef, have a competitive advantage in this area, as they have easy clean-out designs without the need for a shop vac. It’s possible that this may be changing, and an easier method for cleaning out ash is cascading down to other Traeger models.

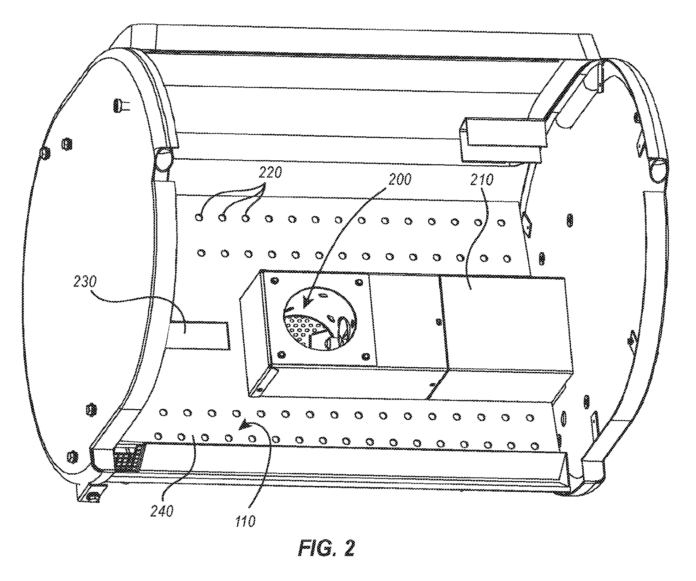

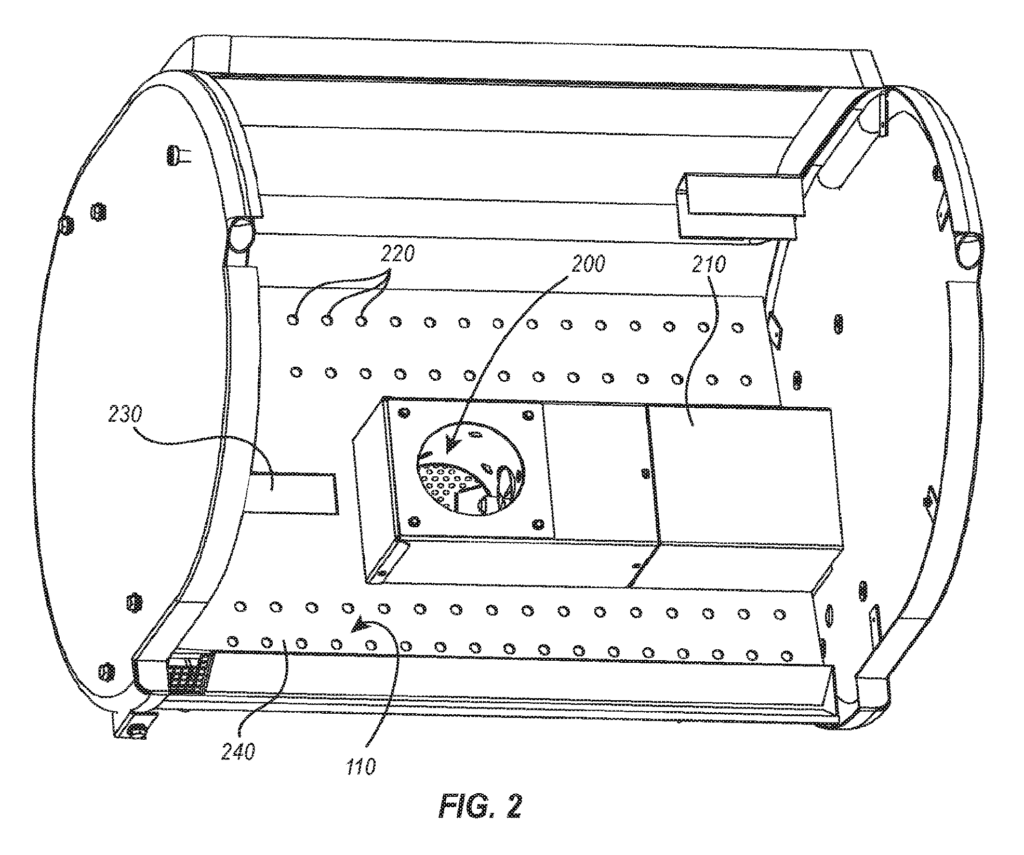

Traeger filed for a patent that was released, shortly before patents on the new Timberline, for “self-cleaning grilling devices”. While it’s pure rumor and speculation whether or not Traeger will ever use this design, it is a design that would work for easy ash clean-out on their lower tiered models. In their patent application, they also describe a potential benefit of this design to create more smoke (we get into that at the end). In the first image below, you can see an overhead diagram of their barrel design with holes in the bottom of the barrel fire pot where ash normally accumulates in their current design.

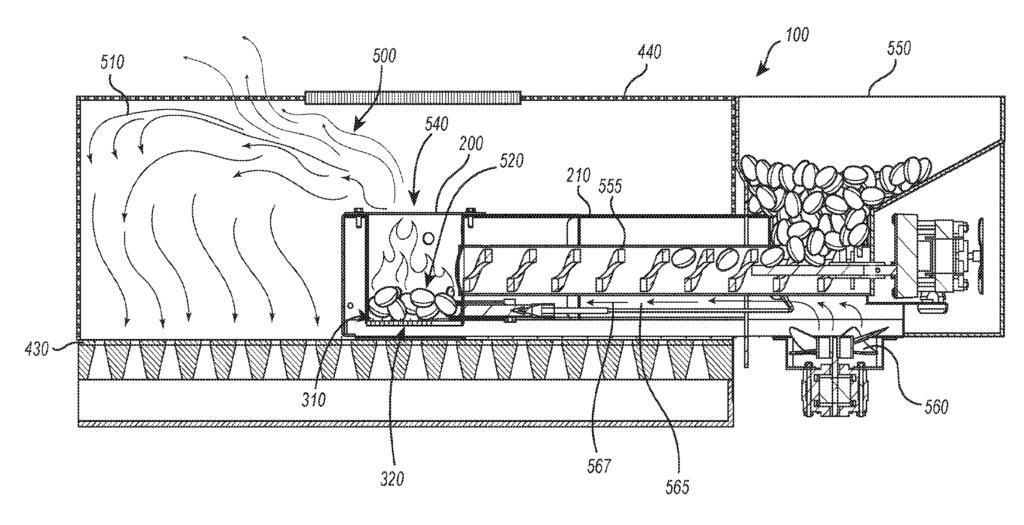

In the next diagram, it shows a cross section of the grill. You can see with this self cleaning design, the ash would fall through the holes shown in the previous image and accumulate between the outer barrel and the floor with the holes in it. The next problem is how to get the ash that accumulated, easily out of the grill.

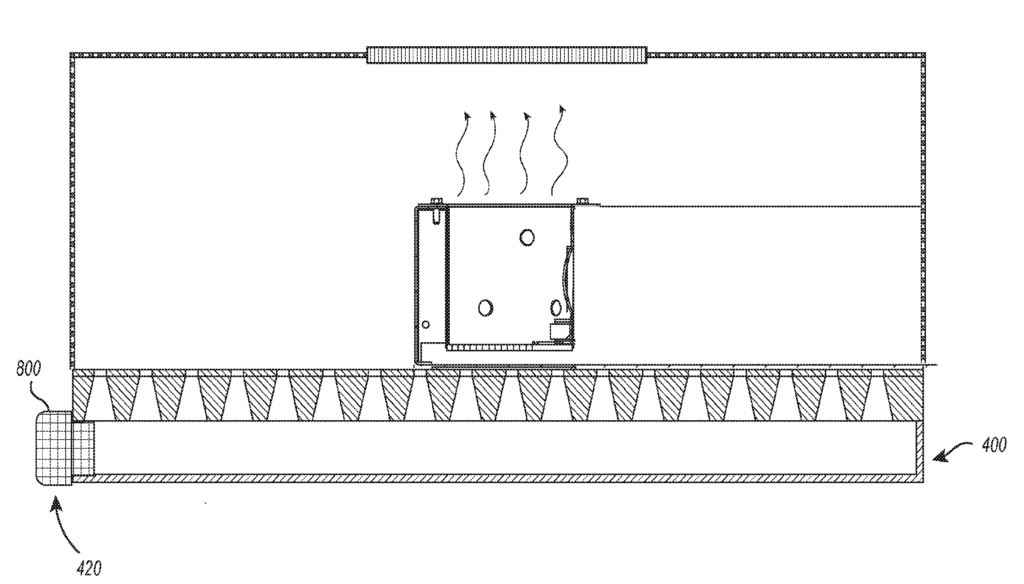

A proposed to solution to that in the patent application is shown in the image below. There is a cap on the end of the grill (number 800 on the diagram) that gives access to the cavity where ash accumulates. You could then easily remove the cap and attach a shop vac to the end of the grill and vacuum all of the ash.

In the patent application, they describe various permutations of this design, all aimed at solving the same problem. They also describe a possible added benefit for increased smoke production. From the application we get a little bit of a science lesson first.

“Combustion of fuel pellets within the firepot may comprise four stages. Within the first stage, the hot-rod heats up and the blower motor actuates air into the firepot causing moisture to evaporate out of the fuel pellets. During the second state, the hydro-carbons within the fuel pellets vaporize. During this state, the desirable smoke is produced. In the following third stage, gas vapor ignition occurs where the actual flame appears. During the fourth stage, char burns off producing ash.”

Then they describe how the design could result in increased smoke production (amended slightly for readability). We’ll summarize after the quote.

“Grouping solid fuel on the landing zone may provide for unique methods of generating smoke without entering the gas vapor ignition stage of combustion. For example, wood pellets may be delivered to the landing zone. Once at the landing zone, the wood pellets are not exposed to the one or more holes in the floor. As such, less oxygen is available to the wood pellets in the landing zone. A heating element (not shown) can then heat the wood pellets to a high temperate without entering the gas vapor ignition stage due to the lack of oxygen and because the second stage of combustion (i.e., the vaporization of hydro-carbons) is an endothermic reaction, which causes the combustion stages to temporarily stall at the second stage. In at least one embodiment, under such circumstances, the wood pellets will generate smoke and remain within the second stage for a prolonged period of time, instead of progressing more quickly into the gas vapor ignition stage. Such a configuration may allow for low temperature smoke to be produced.”

What their calling the landing zone is the area of the fire pot right in front of the opening for the auger, that delivers pellets. Obviously, since the pellets are just being dropped, as opposed to projected, they’ll accumulate in that spot. If the ash holes are positioned so that pellets can accumulate away from any holes, it will restrict their oxygen and create more smoke by not allowing ignition and a flame. The current fire pit design has no holes other than for the auger, so it’s unclear from the patent application if they’re describing a method of avoiding degradation in the amount of smoke produced or if there are any incremental benefits by added oxygen control.

We have no idea if Traeger will implement any of the design ideas described in their patent, but it’s great to see the innovation process. We hope something like this makes its way down to the Trager Ironwood and even the popular Traeger Pro 575 models because it would make routine cleaning much easier.